News

Water immersion sterilization retort/autoclave/sterilizer needs to be tested before starting up. And do you know what tests are required?

(1) Pressure test: After closing the door, set the pressure inside the retort in the "Control Screen", and then observe whether the pressure value displayed on the touch screen is consistent with the reading of the pressure gauge. If inconsistent, calibrate and check for leakage.

(2)Temperature test: Add water to the empty retort and start running. After running to the sterilization stage for 5 minutes, compare the temperature value on the HMI with the MIG value. The temperature value on the HMI should be equal to or slightly smaller than the MIG value.

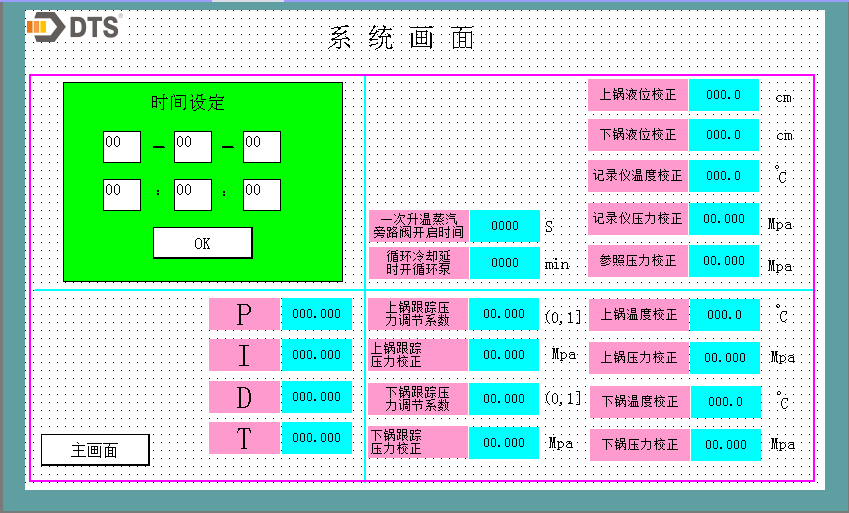

(3)Deviation correction: Click the "System Screen" button in the "Control Screen" to enter this screen. This screen is for adjusting system time, sensor calibration, and setting alarm temperature and pressure. It requires the guidance of professional operators to set up.

Regular inspection and maintenance of retort

The retort is equipped with safety valves, pressure gauges, thermometers and other instruments, which must be kept safe, sensitive and reliable. It should be maintained and calibrated regularly during use.

Pay attention to the following when maintaining electrical components:

(1) Electrical components and connecting wires are prohibited from contact with water. If water splashes, it should be dealt with professionally and turn on the power after confirming it is dry.

(2) The electrical components of the equipment shall be protected against dust, and dust removal maintenance shall be carried out every quarter.

(3) Regularly check whether the connecting terminals and connectors of each connecting cable are loose. If loose, tighten it.

The retort should be inspected regularly, with at least one external inspection every 6 months and at least inspection every year. The preparatory work and inspection items before the inspection should be carried out in accordance with the "Procedures" and relevant regulations, and the inspection report should be archived and filed.