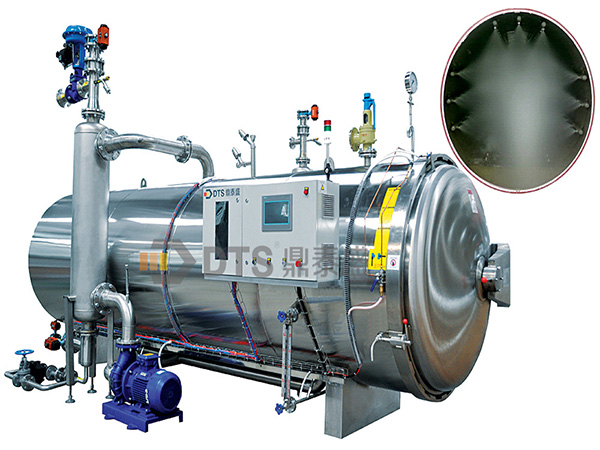

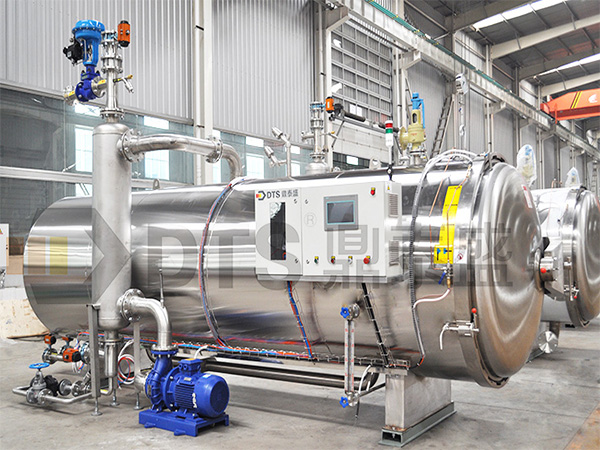

Water spray retort,autoclave,canned retort,retort in food industry,retort machine,retort,sterilization,sterilizer,Heat up and cool down by the heat exchanger, so the steam and cooling water will not contaminate the product, and no water treatment chemicals are needed. The process water is sprayed onto the product through the water pump and the nozzles distributed in the retort to achieve the purpose of sterilization. Accurate temperature and pressure control can be suitable for a variety of packaged products.

Working Principle

Put the product into the sterilization retort and close the door. The retort door is secured by triple safety interlocking. Throughout the whole process, the door is mechanically locked.

The sterilization process is automatically carried out according to the recipe input to the micro-processing controller PLC

Throughout the whole process, the pressure inside the retort is controlled by the program by feeding or discharging compressed air through the automatic valve to the retort. Due to water spray sterilization, the pressure in the retort is not affected by temperature, and the pressure can be set freely according to the packaging of different products, making the equipment more widely applicable (three-piece cans, two-piece cans, flexible packaging bags, glass bottles, plastic packaging etc.).

Advantage

●Accurate temperature control, excellent heat distribution

The temperature control module (D-TOP system) developed by DTS has up to 12 stages of temperature control, and the step or linearity can be selected according to different product and process recipe heating modes, so that the repeatability and stability between batches of products are maximized well, the temperature can be controlled within ±0.5℃.

●Perfect pressure control, suitable for a variety of packaging forms

The pressure control module (D-TOP system) developed by DTS continuously adjusts the pressure throughout the whole process to adapt the internal pressure changes of the product packaging, so that the degree of deformation of the product packaging is minimized, regardless of the rigid container of tin cans, aluminum cans or plastic bottles, plastic boxes or flexible containers can be easily satisfied, and the pressure can be controlled within ±0.05Bar.

●Highly clean product packaging

The heat exchanger is used for indirect heating and cooling, so that the steam and cooling water are not in contact with the process water. The impurities in the steam and cooling water will not be brought to the sterilization retort, which avoids the secondary pollution of the product and does not require water treatment chemicals (No need to add chlorine), and the service life of the heat exchanger is also greatly extended.

DTS has experienced thermal verification experts and is a member of IFTPS in the United States. It fully cooperates with FDA-approved third-party thermal verification agencies. The experience of many North American customers has made DTS familiar with FDA/USDA regulatory requirements and cutting-edge sterilization technology.

●Energy saving and environmental protection

A small amount of process water is quickly circulated to quickly reach the predetermined sterilization temperature.

Low noise, create a quiet and comfortable working environment.

Unlike pure steam sterilization, there is no need to vent before heating, which greatly saves steam loss and saves about 30% of steam.

P-0902

P-1003

P-12-3/4/5

P-14-3/4/5/6

P-16-4/5/6

P-18-5/6

Tin can

Aluminum can

Aluminum bottle

Plastic bottles, cups, boxes, trays

Glass jars, can

Flexible packaging pouch

Tetra Recart

Drinks (vegetable protein, tea, coffee)

Dairy products

Vegetables and fruits

Meat, poultry

Fish and seafood

Baby food: tin cans

Ready-to-eat meals

Pet food: tin can