Double layer tray,autoclave,canned retort,retort in food industry,retort machine,retort,sterilization,sterilizer,The double-layer tray is a kind of food tray with high efficiency, energy saving and good heat distribution developed by dts based on accurate data calculation and a large amount of experimental data. the features are as follow:

The double-layer tray is a kind of food tray with high efficiency, energy saving and good heat distribution developed by dts based on accurate data calculation and a large amount of experimental data. the features are as follow:

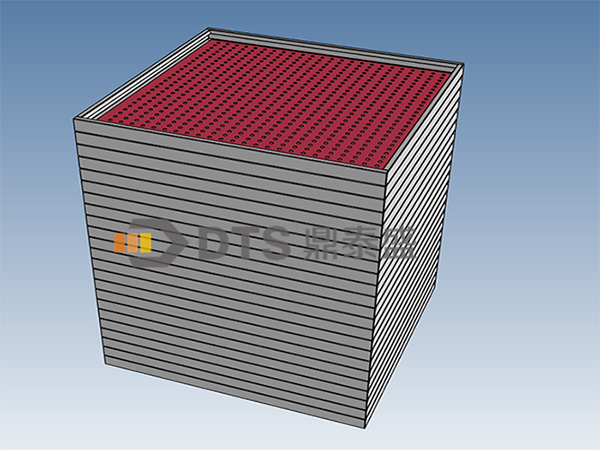

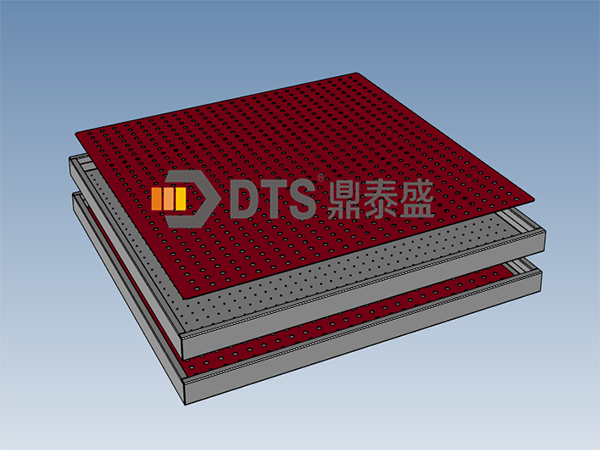

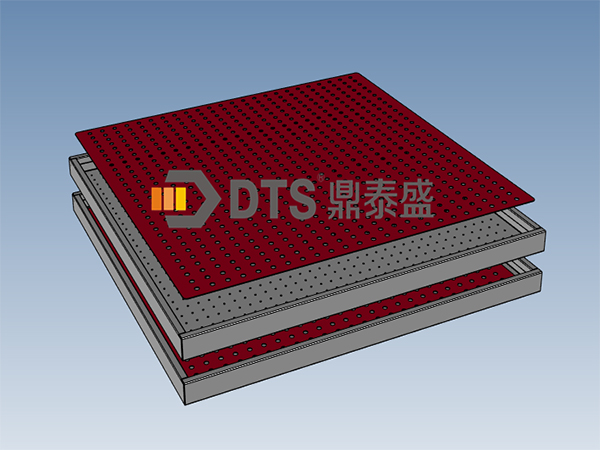

The bottom is double layers that has good heat distribution. the bottom of the food tray has a bottom plate and a double-layer device (the double-layer device can be easily removed for cleaning). each tray is equipped with a double bottom enabling a redistribution of water at each level with streaming. it can ensure that the water flows uniformly from the upper layer food into the lower layer food in all directions without temperature cold areas.

Compared with water immersion retort, it saves circulating water and steam. the food tray can be designed according to the characteristics and process requirements of the customer's product. the water level of the food tray can be designed (within a reasonable range, accurately control the fluid flow and cover the sterilization of a variety of products), which achieves a good heat transfer effect and reduces the consumption of the process water and steam. compared to the water immersion retort, process water saves more than 50% and steam saves more than 40%.

Accurate pressure control.

More than half of the space in the retort is occupied by air, so the pressure control of the retort can achieve extremely high accuracy, helping customers to obtain high-quality sterilization products.

In the entire sterilization process, the upper and lower products are heated to the same degree. during the heating phase, hot water flows from top to the bottom, and the upper product is heated first. because the water in the tray is extremely fluid, the temperature difference between the upper and lower products lasts for a very short time, and the cooling water also flows from top to bottom during the cooling phase and the products are cooled first. so from the perspective of the entire sterilization process, the upper and lower products are heated to the same degree.