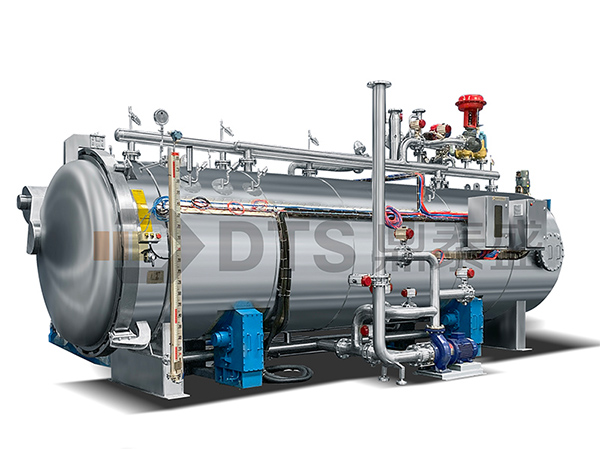

Steam rotary retort,autoclave,canned retort,retort in food industry,retort machine,retort,sterilization,sterilizer,Steam and rotary retort is to use the rotation of the rotating body to make the contents flow in the package. It is inherent in the process that all air be evacuated from the retort by flooding the vessel with steam and allowing the air to escape through vent valves.There is no overpressure during the sterilization phases of this process, since air is not permitted to enter the vessel at any time during any sterilization step. However, there may be air-overpressure applied during the cooling steps to prevent container deformation.

Working Principle

Steam and rotary retort is to use the rotation of the rotating body to make the contents flow in the package. It is inherent in the process that all air be evacuated from the retort by flooding the vessel with steam and allowing the air to escape through vent valves.There is no overpressure during the sterilization phases of this process, since air is not permitted to enter the vessel at any time during any sterilization step. However, there may be air-overpressure applied during the cooling steps to prevent container deformation.

Put the product into the sterilization retort, cylinders are individually compressed and close the door. The retort door is secured by triple safety interlocking. Throughout the whole process, the door is mechanically locked.

The sterilization process is automatically carried out according to the recipe input to the micro-processing controller PLC.

The hot water is injected into the retort through the hot water tank, the cold air in the retort is evacuated, then the steam is injected at the top of the retort, the steam inlet and the drainage are synchronized, and the space in the retort is filled with steam. After all the hot water is discharged, continues heating up to reach the sterilization temperature. There is no cold spot in the whole sterilization process. After the sterilization time is reached, cooling water entered and cooling stage start, and the pressure in the retort is reasonably controlled during the cooling stage to ensure that the cans will not be deformed due to the difference between the internal and external pressures.

In the heating up and holding stage, the pressure in the retort is completely generated by the saturation pressure of steam. When the temperature is lowered, counter pressure is generated to ensure that the product packaging will not be deformed.

During the whole process, the rotation speed and time of the rotating body are determined by the sterilization process of the product.

Advantage

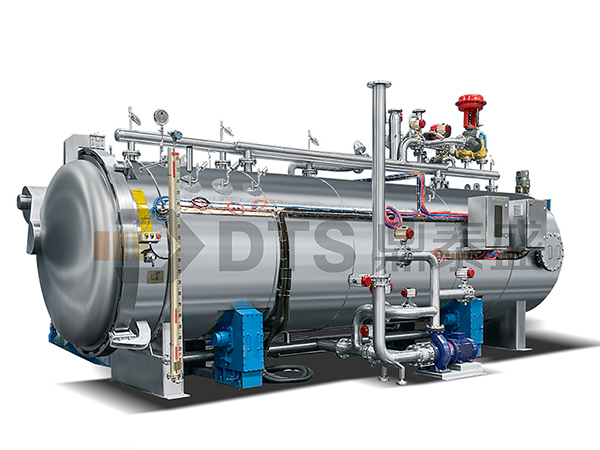

●Uniform heat distribution

By removing the air in the retort vessel, the purpose of saturated steam sterilization is achieved. Therefore, in the end of come-up vent phase, the temperature in the vessel reaches a very uniform state.

●Comply with FDA/USDA certification

DTS has experienced thermal verification experts and is a member of IFTPS in the United States. It fully cooperates with FDA-approved third-party thermal verification agencies. The experience of many North American customers has made DTS familiar with FDA/USDA regulatory requirements and cutting-edgesterilization technology.

●Simple and reliable

Compared with other forms of sterilization, there is no other heating medium for the come-up and sterilization phase, so only the steam needs to be controlled to make the batch of products consistent. FDA has explained the design and operation of the steam retort in detail, and many old canneries have been using it, so customers know the working principle of this type of retort, making this type of retort easy for old users to accept.

●The rotating system has a simple structure and stable performance

The rotating body structure is processed and formed at a time, and then balanced treatment is performed to ensure the stability of the rotation

The roller system uses an external mechanism as a whole for processing. The structure is simple, easy to maintain, and greatly extend the service life.

The pressing system adopts double-way cylinders to automatically divide and compact, and the guide structure is stressed to prolong the service life of the cylinder.

Z-X14-2/3/4

Z-X16-3/4/5

Z-X18-4/5/6

Tin can

Beverages(vegetable protein, tea, coffee)

Vegetable and fruit(mushroom, vegetables, beans)

Meat, poultry

Fish, seafood

Babyfood

Ready to eat food, porridge

Pet food