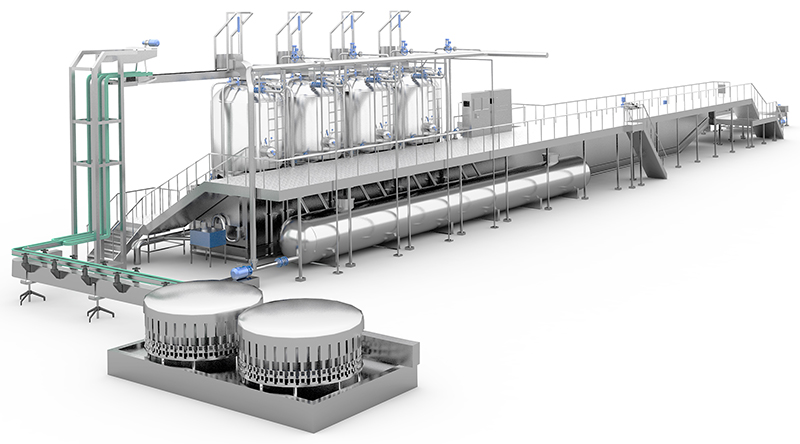

Vertical Crateless Retort System,autoclave,canned retort,retort in food industry,retort machine,retort,sterilization,sterilizer,Continuous crateless retorts sterilization line has overcome various technological bottlenecks in the sterilization industry, and promote this process on the market. The system has high technical starting point, advanced technology, good sterilization effect, and simple structure of the can orientation system after sterilization. It can meet the requirement of continuous processing and mass production.

Continuous crateless retorts sterilization line has overcome various technological bottlenecks in the sterilization industry, and promote this process on the market. The system has high technical starting point, advanced technology, good sterilization effect, and simple structure of the can orientation system after sterilization. It can meet the requirement of continuous processing and mass production.

●High technical starting point, good sterilization effect, uniform heat distribution

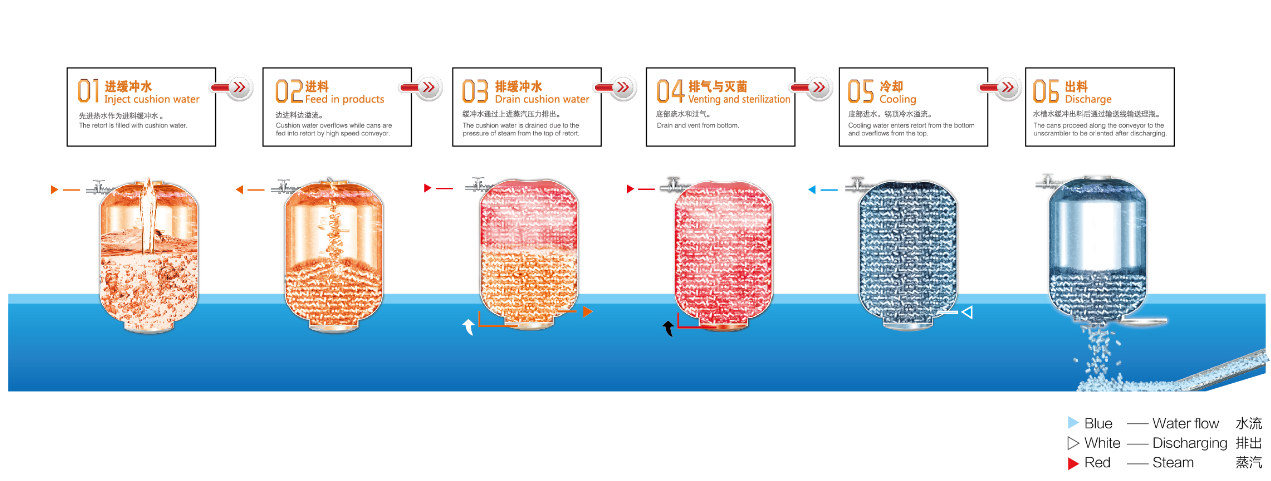

Advanced vent technology is adopted to ensure the temperature distribution is controlled at ±0.5℃ with good sterilization effect.

●Short process preparation time

The products can enter the retort for processing within one minute without the basket loading and waiting. Hot filling product low heat loss, high initial temperature, reduces the contact with atmosphere and maintains the original quality of the products.

●High control accuracy

High precision temperature and pressure sensors are adopted to realize the whole temperature and pressure control. The temperature fluctuation in the holding phase can be controlled at plus or minus 0.3 ℃.

●Tractability

Sterilization data (time, temperature and pressure) of each batch of products and each time period can be checked and traced at any time.

● Energy-saving efficiency

steam injection from top, saving steam consumption

Lower steam waste from bleeders, and no dead corner

Because the hot buffer water is injected into the retort vessel with same temperature as the product filling temperature (80-90℃),so the temperature difference is reduced, thus heating time is reduced.

●Dynamic image display

The running status of the system is displayed dynamically through the HMI, so that the operator is clear about the process flow.

●Parameter easy adjustment

According to the different needs of the product, set the time, temperature and pressure required by the process, and directly use the corresponding digital input data on the touch screen.

●High configuration

Key parts of the system materials, accessories are selected excellent brand (such as: valves, water pumps, geared motor, conveyor chain belt, visual inspection system, hydraulic control system, electrical control system, etc.) to ensure the stable performance of the system, extend the service life.

●Safe and reliable

Adopt double safety valve and double pressure sensing control, equipment vertical structure, door is located at the top and the bottom, eliminate safety hidden danger;

Alarm system, abnormal situation will be displayed on the touch screen in time with sound prompt;

The recipe is protected with multi-level password to eliminate the possibility of misoperation.

The wholeprocess pressure protection can effectively avoid product packages deformation.

After the system is restored after power failure, the program can automatically restore to the state before power failure.